Introduction

Human Machine Interface (HMI) technology is at the forefront of industrial automation, revolutionizing how humans interact with machines. As industries move toward digitalization and smart manufacturing, HMI plays a critical role in enhancing efficiency, productivity, and safety. This article explores how HMI technology is transforming industrial automation, its key components, benefits, and future trends.

Definition

A Human Machine Interface (HMI) is a system or device that enables interaction between humans and machines, typically through a graphical user interface (GUI), touchscreens, buttons, or control panels. It allows users to monitor, control, and manage industrial processes, automation systems, or digital devices efficiently. HMIs are widely used in manufacturing, healthcare, automotive, and other industries to improve user experience, streamline operations, and enhance productivity.

Understanding Human Machine Interface (HMI)

HMI refers to the user interface that connects operators to industrial machinery and automation systems. It enables real-time monitoring, control, and data visualization, facilitating seamless communication between humans and machines. HMIs can range from simple push-button panels to advanced touchscreen displays with graphical user interfaces (GUIs).

Key Components of HMI Technology

HMI technology consists of several crucial components that enable smooth interaction between humans and machines:

- Hardware: Includes display screens, input devices (touchscreens, keyboards, and buttons), and processors.

- Software: HMI software provides visualization, data analytics, and control capabilities, often integrated with SCADA (Supervisory Control and Data Acquisition) systems.

- Connectivity: Interfaces such as Ethernet, USB, and wireless networks allow HMIs to communicate with programmable logic controllers (PLCs), sensors, and industrial IoT (IIoT) devices.

- Security: Advanced cybersecurity features protect industrial systems from unauthorized access and cyber threats.

The Role of HMI in Industrial Automation

HMI technology has significantly enhanced industrial automation in several ways:

1. Enhanced Monitoring and Control:

Modern HMI systems provide real-time data visualization, allowing operators to monitor machine performance, detect anomalies, and make informed decisions. Graphical representations of industrial processes enable intuitive monitoring, reducing the likelihood of human errors.

2. Increased Productivity and Efficiency:

With intuitive controls and automated workflows, HMI minimizes manual intervention, reducing downtime and improving overall efficiency. Operators can quickly troubleshoot issues, optimize processes, and ensure seamless operations.

3. Improved Safety and Compliance:

HMI technology helps enforce safety protocols by providing alerts, warnings, and automated shutdowns in case of emergencies. Compliance with industry regulations is also simplified through real-time data logging and reporting.

4. Integration with IIoT and Industry 4.0:

As part of the Industry 4.0 revolution, HMI integrates with Industrial Internet of Things (IIoT) devices, enabling predictive maintenance, remote monitoring, and data-driven decision-making. Cloud-based HMIs allow operators to access system information from anywhere, improving operational agility.

5. Customization and Scalability:

Modern HMI solutions are highly customizable, allowing industries to tailor interfaces according to specific requirements. Scalable architectures ensure that HMI systems can adapt to growing automation needs without major overhauls.

Applications of HMI Technology in Industrial Sectors

HMI technology is transforming multiple industrial sectors, including:

- Manufacturing: Automated assembly lines, robotic systems, and production monitoring are enhanced by HMI for seamless operation.

- Energy and Utilities: Power plants, water treatment facilities, and oil refineries use HMI for real-time monitoring and control.

- Automotive: Car manufacturing plants leverage HMI for robotics control and quality assurance.

- Food and Beverage: HMI aids in automated packaging, temperature control, and process optimization.

- Healthcare and Pharmaceuticals: Precision manufacturing of medical devices and drug production benefit from advanced HMI systems.

Benefits of Implementing HMI Technology

Industries adopting HMI technology experience several advantages:

- User-Friendly Interfaces: Intuitive designs reduce training time and improve user engagement.

- Real-Time Data Access: Immediate insights enable proactive decision-making.

- Reduced Downtime: Faster diagnostics and troubleshooting enhance system uptime.

- Cost Savings: Automation minimizes labor costs and optimizes resource utilization.

- Remote Access: Cloud-based HMI solutions allow remote monitoring and control.

Challenges in Human Machine Interface (HMI) Market

High Implementation Costs:

One of the major challenges in the HMI market is the high cost of implementation. Advanced HMI systems require expensive hardware, software, and integration with existing industrial setups. Small and medium-sized enterprises (SMEs) often struggle to afford these systems, limiting market penetration.

Cybersecurity Risks:

With the increasing use of cloud-based and IoT-integrated HMI systems, cybersecurity has become a significant concern. These interfaces often connect to critical industrial systems, making them vulnerable to cyberattacks, data breaches, and unauthorized access. Ensuring robust security measures is a constant challenge for HMI developers.

Complexity in Integration:

HMI systems need to integrate seamlessly with existing industrial machinery, software platforms, and enterprise systems. However, many legacy systems lack compatibility with modern HMI solutions, requiring extensive customization. This complexity increases implementation time and costs for businesses.

User Experience and Training:

An intuitive user interface is crucial for the success of any HMI system. However, designing user-friendly HMI solutions that cater to both novice and expert users is challenging. Additionally, employees often require specialized training to operate and maintain these systems, adding to the overall cost and time investment.

Evolving Industry Standards:

The HMI industry is constantly evolving, with new standards and regulations emerging frequently. Compliance with safety, usability, and connectivity standards varies across regions, making it difficult for manufacturers to develop universally accepted solutions. Keeping up with these changes requires continuous innovation and investment.

Future Trends in HMI Technology

As industrial automation continues to evolve, several emerging trends are shaping the future of HMI technology:

Artificial Intelligence (AI) and Machine Learning (ML): AI-powered HMI systems enhance predictive maintenance and process optimization.

Augmented Reality (AR) and Virtual Reality (VR): AR/VR-based HMIs improve operator training and remote troubleshooting.

Voice-Activated Interfaces: Voice commands streamline interaction with industrial systems.

Wearable HMIs: Smart glasses and wearable devices provide hands-free access to critical information.

Cybersecurity Enhancements: Advanced encryption and authentication mechanisms improve system security.

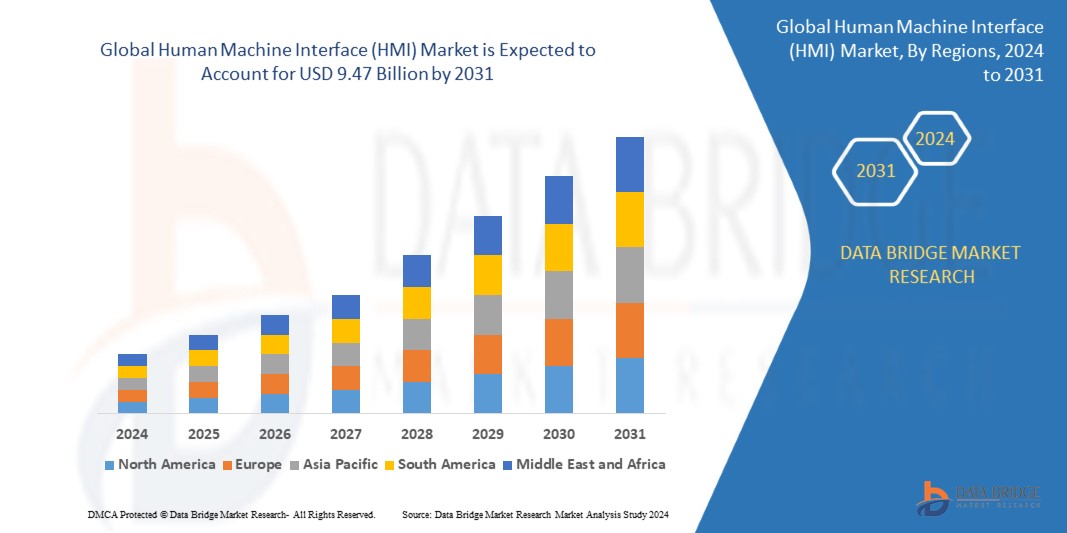

Expansion Rate of Human Machine Interface (HMI) Market

According to Data Bridge Market Research, the size of the global human machine interface (HMI) market was estimated at USD 5.07 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 8.12% from 2024 to 2031, reaching USD 9.47 billion.

Read More: https://www.databridgemarketresearch.com/reports/global-human-machine-interface-hmi-market

Conclusion

HMI technology is revolutionizing industrial automation by bridging the gap between humans and machines. Its role in enhancing monitoring, control, safety, and efficiency makes it a cornerstone of modern smart manufacturing. As advancements in AI, AR, and IoT continue, HMI technology will play an even more significant role in shaping the future of industrial automation.