In any industrial sector, the efficiency, reliability, and durability of equipment play a crucial role in ensuring seamless operations. One of the most critical components in various industries is valves and fittings. These components help regulate fluid and gas flow, making them indispensable in manufacturing, energy, chemical, pharmaceutical, and other sectors. Choosing a reliable valve and fittings manufacturer can make a significant difference in the quality and performance of industrial processes.

Why Quality Valves and Fittings Matter

Valves and fittings are essential components used in fluid control systems. They ensure that liquids and gases flow efficiently, preventing leaks and maintaining pressure stability. High-quality valves and fittings contribute to:

- Operational Efficiency – Properly functioning valves help maintain optimal performance in industrial systems, reducing downtime and operational disruptions.

- Safety – Well-manufactured valves and fittings prevent leaks, pressure build-up, and hazardous situations, ensuring workplace safety.

- Cost-Effectiveness – Durable and high-quality components reduce maintenance costs and enhance system longevity, leading to long-term savings.

- Regulatory Compliance – Industries must adhere to strict safety and operational standards. Reliable manufacturers produce components that meet or exceed regulatory requirements.

Key Features of a Reliable Valve and Fittings Manufacturer

Choosing the right manufacturer is vital to ensure the durability, reliability, and efficiency of industrial systems. Here are some critical aspects to consider:

1. High-Quality Materials

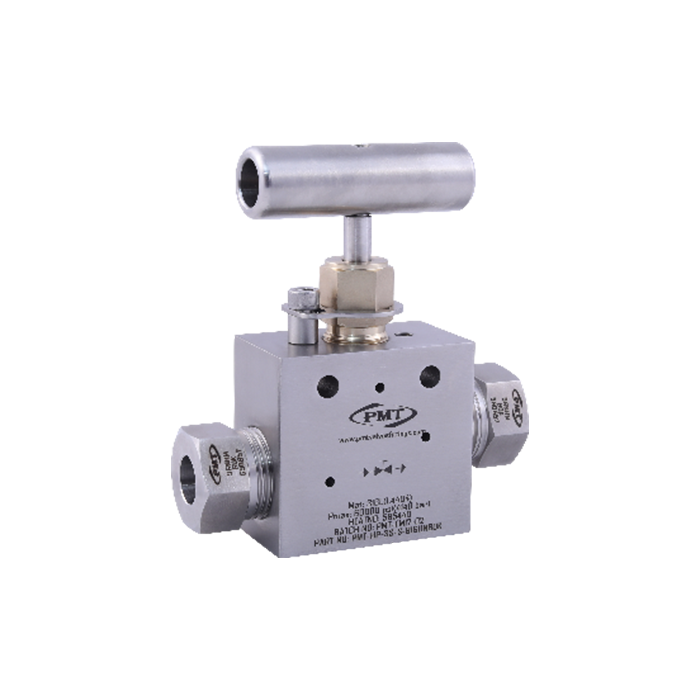

Reliable manufacturers use superior materials such as stainless steel, brass, and specialized alloys to ensure the longevity and efficiency of their valves and fittings. The choice of material depends on factors such as pressure requirements, corrosion resistance, and operational environment.

2. Advanced Manufacturing Techniques

Precision engineering and cutting-edge manufacturing processes contribute to the durability of Valve and Fittings Manufacturer. CNC machining, automated welding, and rigorous quality control testing help achieve high accuracy and superior product performance.

3. Industry-Specific Solutions

Different industries require specialized valves and fittings. A reputable manufacturer offers customized solutions to cater to specific needs, whether it’s for oil and gas, chemical processing, food and beverage, pharmaceuticals, or water treatment industries.

4. Strict Quality Control and Testing

To ensure reliability, manufacturers conduct stringent quality control tests, including:

- Pressure testing

- Leak detection

- Corrosion resistance evaluation

- Temperature tolerance assessment

5. Certifications and Compliance

A reliable manufacturer adheres to international quality and safety standards such as ISO 9001, ASME, API, and ANSI. These certifications demonstrate a commitment to excellence and regulatory compliance.

Industries That Rely on Quality Valves and Fittings

Valves and fittings are used in various industries, each requiring specific designs and materials to meet operational demands. Some of the key industries include:

1. Oil and Gas Industry

In the oil and gas sector, valves control the flow of crude oil, natural gas, and refined products. These components must withstand high pressure, extreme temperatures, and corrosive substances.

2. Chemical and Petrochemical Industry

Valves and fittings in this industry must handle aggressive chemicals, high temperatures, and complex flow control requirements. Corrosion-resistant materials like stainless steel and special alloys are essential.

3. Water and Wastewater Treatment

Reliable valves regulate water distribution and wastewater treatment processes. Durability and resistance to contamination are key factors in selecting components for this industry.

4. Food and Beverage Industry

Sanitary valves and fittings are required to maintain hygiene and prevent contamination in food and beverage processing. Manufacturers provide FDA-approved and stainless-steel components to meet industry standards.

5. Pharmaceutical Industry

High-precision valves and fittings are used in the pharmaceutical sector to ensure accurate fluid control and maintain sterility in drug manufacturing processes.

6. HVAC and Plumbing Systems

Valves and fittings are crucial in heating, ventilation, air conditioning (HVAC), and plumbing applications to regulate water and gas flow efficiently.

How to Choose the Best Valve and Fittings Manufacturer

Selecting a reliable manufacturer involves evaluating several key factors:

1. Reputation and Experience

Look for a manufacturer with a strong industry reputation and years of experience. Customer reviews, testimonials, and case studies can provide insights into their reliability.

2. Product Range and Customization

A good manufacturer offers a diverse range of valves and fittings while also providing customization options to meet specific industry needs.

3. Technical Support and Customer Service

Top manufacturers provide excellent customer support, technical assistance, and after-sales service to ensure smooth operations.

4. Competitive Pricing and Value for Money

While cost is a consideration, quality should never be compromised. A manufacturer offering durable, high-quality products at competitive prices provides better long-term value.

5. Global Reach and Distribution Network

A manufacturer with a robust distribution network ensures timely delivery and availability of products across different regions.

Conclusion

Choosing a reliable valve and fittings manufacturer is crucial for the efficiency, safety, and cost-effectiveness of industrial operations. High-quality materials, precision engineering, strict quality control, and industry compliance are essential attributes of a trusted manufacturer. Industries such as oil and gas, chemical processing, water treatment, food and beverage, pharmaceuticals, and HVAC systems rely on well-designed valves and fittings to maintain optimal performance. By selecting a reputable manufacturer, businesses can enhance productivity, reduce maintenance costs, and ensure long-term reliability.