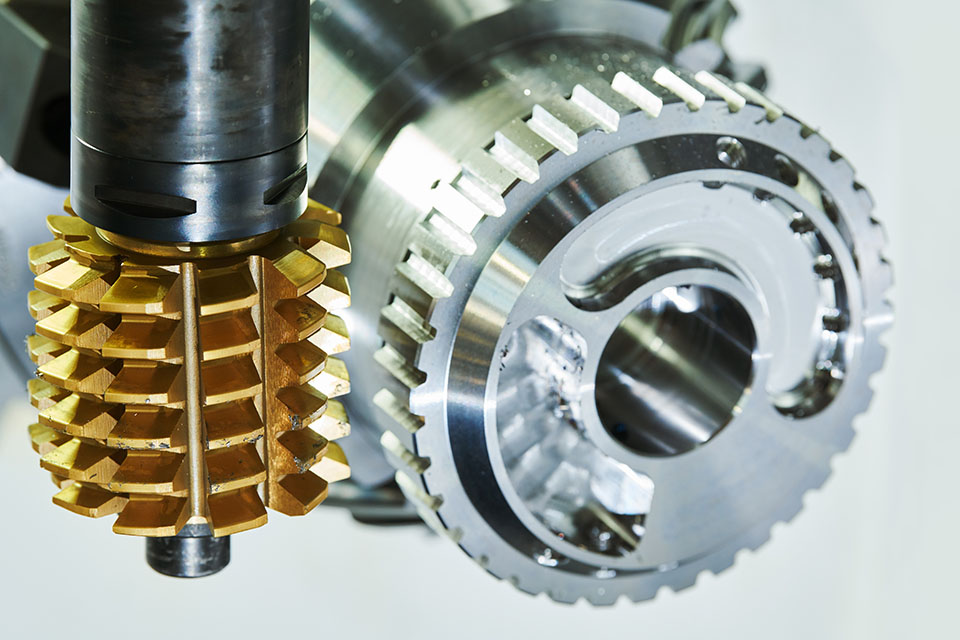

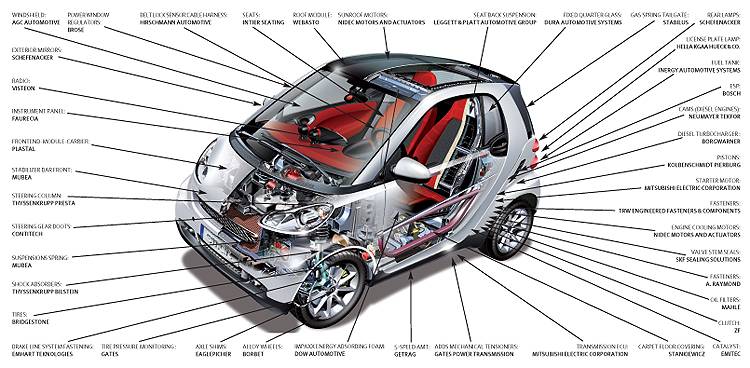

Modern engineering and manufacturing rely on precision and efficiency. The gear manufacturing industry is a major player in today’s economy. Many other sectors rely on gear hob manufacturers to run smoothly. Gears are essential for the effective transmission of torque. The mechanical and industrial worlds will come to a halt. Expert gear manufacturing methods are used to ensure flawless results. Gear hobbing is a typical kind of procedure.

Rate Of Speed

Gear hobbing is a relatively fast process compared to other gear manufacturing techniques. The machine’s simplicity means it needs less attention during operation. Some gears may even be stacked in many hobbed sections simultaneously.

Accuracy

Gears of more excellent quality may be made by hobbing with the right expertise.

Being Flexible

Many possible gear variations are tailored to particular applications due to the wide variety of hobs and hobbing machines.

Raised Efficiency

Enhanced production efficiency is a result of our state-of-the-art gear hobs. Scalability, reduced production costs, and reduced lead times are all outcomes of our CNC-driven hobbing machines. Because our hob machine is versatile, we can make different types of gears without

Achieving An Ideal Surface Finish

A flawless surface polish guarantees a seamless transmission of torque. We provide expert hobbing services to save the gears from wearing down too quickly. Equipment with a smooth surface finish lasts longer, looks better, and has a higher visual appeal. Thanks to the smooth surface, you can save time and money by reducing the need for extra post-processing.

Personalization

It is your one-stop shop for custom gear manufacturing solutions. The CNC gear hobbing machine we use can make gears of varying diameters. We can track specific combinations of gear sizes, diameters, and tooth shapes. Please consult with our engineers for any of your custom gear hobbing requirements.

The gear hobbing machine may make teeth with any shape or pattern of teething. The synchronized motion of the cutting edges creates the tooth profile. The cycle time may be significantly reduced when the cutting edges are aligned parallel. It allows for rapid and accurate cutting. The gear hob’s adaptability will also enable users to make almost any gear.

It has a short production cycle and can make any gear. Thread rolling dies manufacturers in india is an easy way to index. The number of teeth that may be developed might vary from one to four. Using a gear-honing machine also allows for the creation of herringbone gears. It can be a helpful tool for industries that need precise products.

Making significant and tiny pinions is possible using the gear hobbing process. It is possible to manufacture gears of any size or shape. In addition to gearing machines, gear hobbing machines may produce parts too large for gearing machines. The term “gear hobbing machine” describes an automated system that uses sequential indexing to make gears.

It may sharpen planetary gears as well as spur gears. The machine’s external tooth-cutting attachment allows for a very sensitive tooth-cutting process. It may also be used for axial gear hobbing. An interlocking operator door and complete safety enclosures are just two of the many safety features of this machinery.